Taking the Hassle Out of Slurry Pump Maintenance - Reliability Matters

Seals, typically either packing or a mechanical seal, are one of the components most often replaced in a slurry pump. Abrasive particles can easily wear through packing or clog mechanical seal components. In either case, seal life in a slurry environment can quickly be reduced down to weeks or even days. In operations where downtime can cost tens of thousands of dollars an hour, you can reap significant rewards by choosing not only the best sealing solution but also one that is easy and quick to replace. In this post, we’ll focus on some of the best practices to speed up

Common Faults & solutions of Slurry Pumps

Cheryl Tiwanac-Isidro on LinkedIn: Transform Concrete Surfaces

How Does GIW Support Customers?

Pump Industry Winter 2019 Digital Edition by Monkey Media - Issuu

PUMP, Healthy Life for Students

Sulzer increases reliability and performance for offshore industry - Bearing Tips

How to do preventive maintenance of a Slurry Pump?

Slurry pumping services - Metso

Slurry Pump Issues and How to Overcome Them: Common Problems and Solutions

236b0e12 4, PDF, Pump

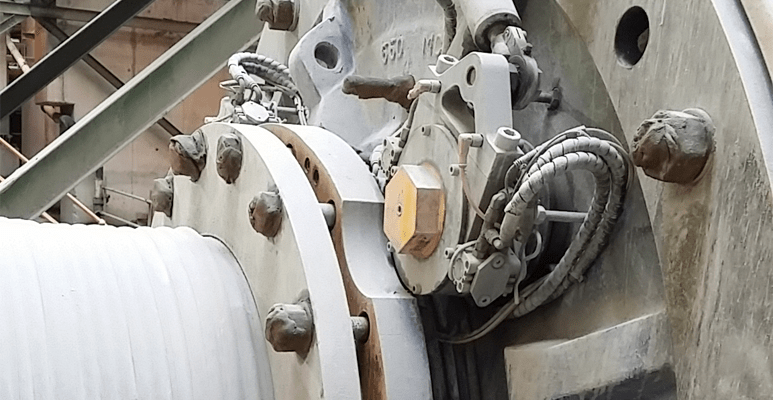

Enhancing pump maintenance with adjustment technology - Mining Technology

Select A Slurry Pump, Huge Inventory Available

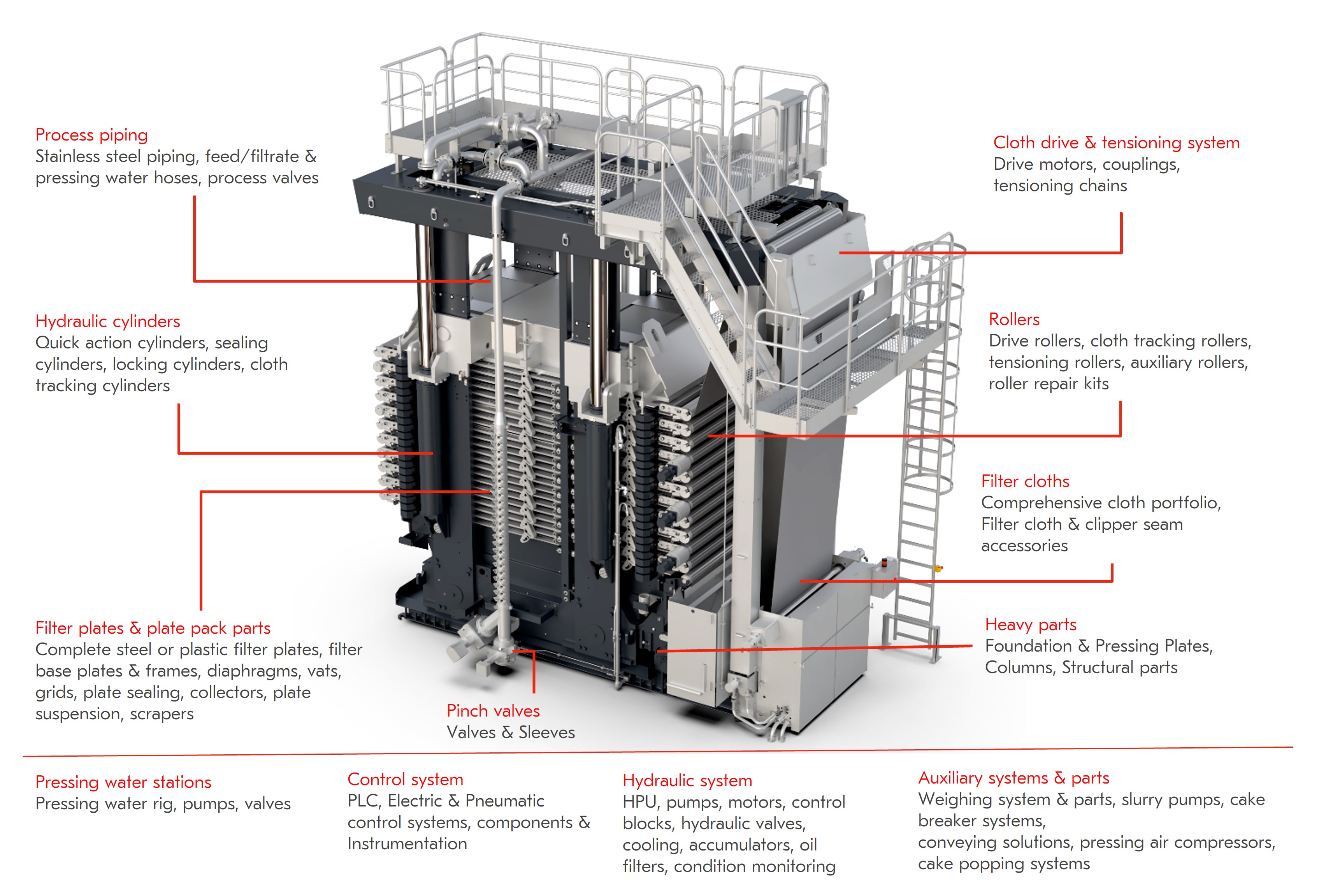

Larox filter services - Metso